ABOUT US

Powering B.C. for Over 50 Years

Power-West was founded in 1975 with a simple promise: do the work with honesty and stand by our word. Fifty years later, we’re proud to carry that tradition forward while equipping our customers with the latest in power solutions. Family-driven values remain at the core of everything we do.

Built on Integrity. Powered by Expertise.

Our History

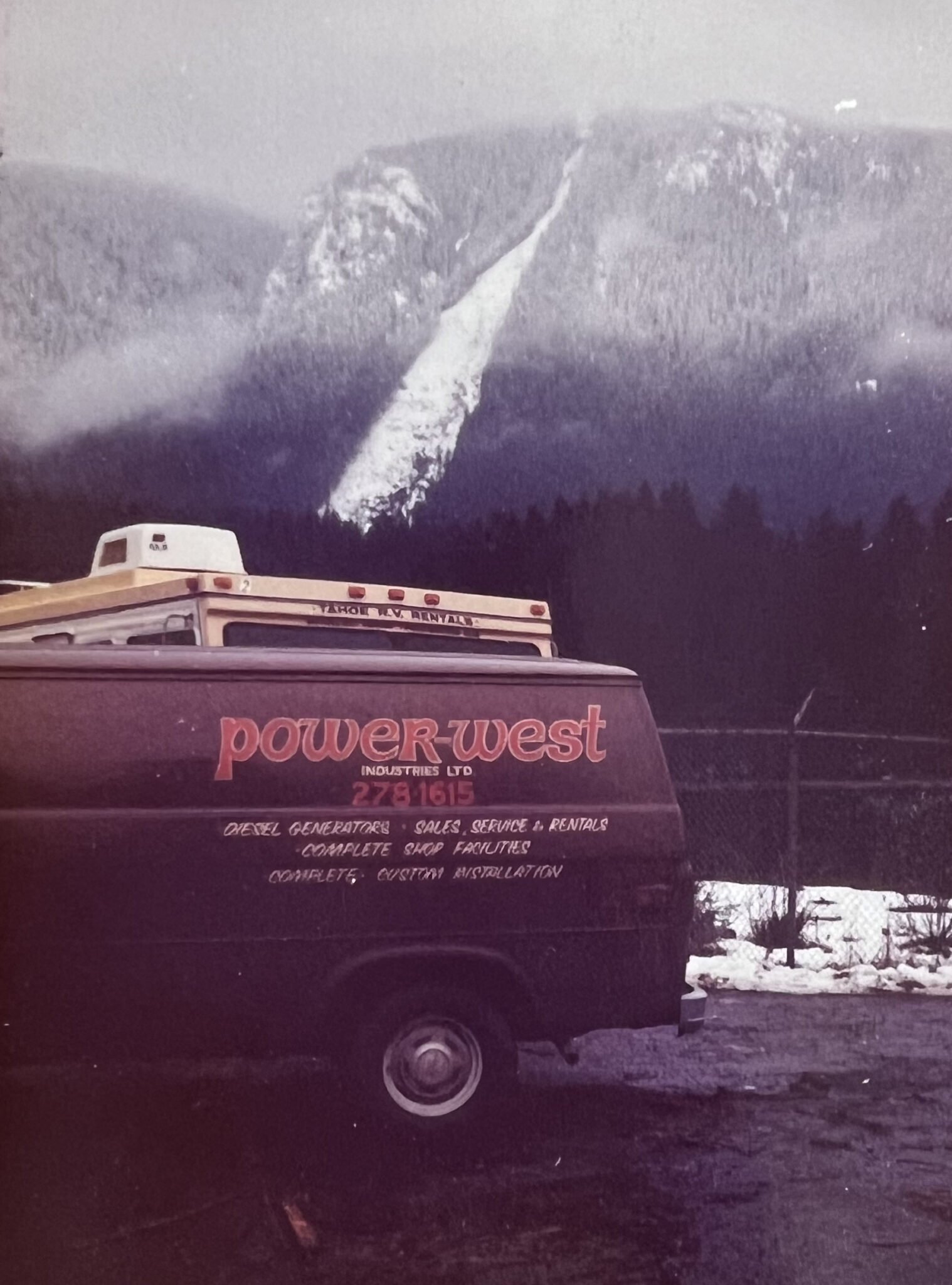

Founded in 1975. Still going strong.

From a small family shop to a trusted industry leader, Power-West has grown alongside British Columbia for 50 years.

1970s

Founded in 1975 by Ronald Cooper, Power-West built its reputation on integrity, hard work, and keeping every promise to customers.

1980s

As demand for reliable power grew, Power-West expanded its service team and became known across B.C. for dependable generator services.

1990s

With new industrial and commercial clients, the company embraced modern equipment and earned a reputation for solving complex challenges.

2000s +

Ryan Cooper took the helm in 2011, blending family values with advanced technology, expanding Power-West into a leading provider.

WHO WE ARE TODAY

Modern Power Solutions. Proven Teamwork.

Power-West has grown into a full-service provider of generator rentals, installations, and maintenance for commercial and industrial clients across British Columbia.

Our certified technicians and support staff are trained on the latest technology, equipped to handle everything from routine service to complex emergency power challenges.

At our core, we remain a family-driven company that values integrity, teamwork, and reliability — but today we match those values with state-of-the-art tools and a dedicated team focused on keeping businesses and communities running without interruption.

Our Values

Our values are more than words on a page. They shape the way we work with each other, with our customers, and with our community. Every project is an opportunity to prove why Power-West has earned trust for nearly five decades.

The Power-West Difference

Owner & CEO

Ryan Cooper

He carries forward the vision his father began in 1975. After earning his Red Seal as a Heavy-Duty Equipment Mechanic and gaining experience at Cummins Western Canada, he returned to Power-West and stepped into leadership in 2011. He continues to guide the company with integrity and reliability while embracing new technology. Ryan also stays hands on, visiting job sites and supporting crews directly, including during the Coquihalla floods in November 2021.

Committed to a Cleaner Future

We take responsibility for how our work impacts the environment. From recycling oils and batteries to building a solar-ready facility, we make sure every step is done with care and sustainability in mind.

Ready When You Need Us

From planned projects to unexpected emergencies, Power-West is here to deliver dependable generator solutions. Connect with our team today and get the support you need to keep your business running.